Preschool Classroom Chairs are designed specifically for preschool and daycare classrooms. The seat back is constructed from a one-piece injection-molded polypropylene shell with a rounded handle hole for easy grip and transport. The lower frame consists of a four-legged powder-coated steel tube frame with curved, upward-curved front legs for enhanced support and TPE non-slip foot covers.

Preschool Classroom Chairs Features

Lightweight and Durable

The PP shell has a wall thickness of 2.5–3.0 mm and the steel tube frame measures Ø19 × 1.2 mm. The Preschool Classroom Chairs weigh approximately 3.2–3.8 kg. They have a static load capacity of ≥120 kg and have passed 10,000 sitting and reclining cycles and 1,000 lateral swing tests. The foot covers are durable and will not loosen even after frequent use, ensuring they meet the demands of long-term kindergarten use.

Size Compatibility

Four seat heights are available: 22/26/30/34 cm, covering heights of approximately 85–135 cm. Seat width: 30–34 cm, depth: 28–31 cm, backrest height: 24–28 cm. Classes within the same series can be mixed across grades; upgrading requires only changing the seat height.

Safety Rounded Corners

All outer edges are chamfered R ≥ 3 mm, and the leading edge of the seat is rounded to prevent pressure on the legs. The handle holes are 2 mm thickened for a comfortable grip. Preschool Classroom Chairs have no exposed screws or sharp corners, reducing the risk of bumps during chasing or moving, and comply with kindergarten safety regulations.

Ergonomics

The backrest reclines 100–103° to align with the spinal curve, and the seat tilts 2–3° higher in front and lower in the back to promote a neutral pelvic position. The slightly curved seat distributes pressure across the sitting bones, and the back vents are 45–55 mm in diameter for breathability. Comfortable for reading or drawing for 30–40 minutes.

Anti-slip and Quiet

The TPE large-surface footpads have a static friction coefficient of μ≥0.55 on tile/wood floors, and dragging noise is ≤50 dB, making them ideal for library corners and multi-purpose classrooms, allowing for easy movement without disturbing others. The footpads are replaceable for low maintenance.

Easy to Clean and Stain-Resistant

The high-gloss PP material is resistant to watercolors, glue sticks, and dust, and can be wiped 1,000 times with a damp cloth and a neutral detergent without noticeable fading. The metallic powder coating is 60–80 μm thick and withstands salt spray for ≥72 hours without blistering. It also withstands daily alcohol/chlorine disinfection without damaging the surface.

Stable Stacking

Ten–12 of the same model can be safely stacked, with a spacing of 45–55 mm between each footpad to prevent sticking. A stack of 12 stands approximately 1.45 m high, and a cart can transport the entire stack at once. After class, stacking along the wall occupies only approximately 0.35–0.4 m², freeing up space for activities.

Environmentally friendly and customizable

Preschool classroom chairs are BPA-free and heavy metal-free, and offer RoHS/REACH material compliance. Custom Pantone colors are available, and the chair backs can be laser-marked with class numbers. They are typically packaged in boxes of 4–6 chairs for easy on-site delivery and inventory.

Standard classrooms in public kindergartens

For daily teaching areas for mixed or group classes for children aged three to six, it is recommended to arrange seats of varying heights by height and color-coded chair backs. During morning reading and group lessons, chairs are arranged according to designated seating arrangements. During breaks, chairs are folded and arranged along the wall. Caregivers transport chairs in stacks of ten to twelve on carts. After floor cleaning, chairs are quickly returned to their designated positions according to barcodes, improving classroom transition efficiency and kindergarten management.

Early Childhood Education Center Sensory Integration Classrooms

The space is primarily zoned for activities, with frequent unit transitions. Preschool classroom chairs must be handled with care and moved quietly. A safe corridor is established between the balance beam and the cushions before class. After class, teachers guide children to return the preschool classroom chairs to their designated locations and disinfect them, creating a self-service process. During parent-attending classes, waiting areas are provided, and the space is restored within two minutes of class.

Children's Canteen Lunch Area

Before meals, childcare workers arrange seats according to the number of children. After meals, children leave in order, following the left aisle. Preschool classroom chairs are hung upside down under the tabletop to free up space for cleaning. The on-duty student then returns them to their designated positions. If the floor is wet during rainy days, the shoes are wiped dry at the entrance's shoe-changing area. The chair legs provide a stable grip, reducing the risk of slipping and falls, ensuring a fast serving and high turnover rate.

Community Library Children's Activity Room

Weekend picture book plays and parent-child reading require flexible circular arrangements. Before the activities begin, librarians arrange the preschool classroom chairs to form a central performance area. Afterward, they are stacked and returned to the wall storage area according to the color guides on the bookcases. For stone or PVC floors, soft mats are used on the chair legs to reduce scratches and reduce noise. Library disinfection records are posted on the underside of the chair backs to ensure transparent and traceable public health practices.

Walmart's back-to-school display at the chain retail store

Products are primarily displayed in stacks, with stack heights limited to 1.5 meters and secured with nylon tie-downs. Seat heights are marked on the end shelves and at the top of the stacks to facilitate parental selection by grade level. A trial seating area is located three meters from the main aisle to minimize congestion. During nighttime replenishment, entire stacks are removed from the back warehouse and repositioned according to price tags and color charts, improving display efficiency and reducing inventory errors.

IKEA's children's experience area at the furniture store

Shopping guides display various combinations of seat and table heights, with height gauges provided nearby to help parents match sizes on-site. The experience area is regularly cleaned and sprayed with disinfectant, and items are returned to their designated locations after completion. A QR code guides customers to check the box quantity and color availability. After placing an order, customers pick up their items from the warehouse in one go, reducing trips and improving decision-making speed for family orders.

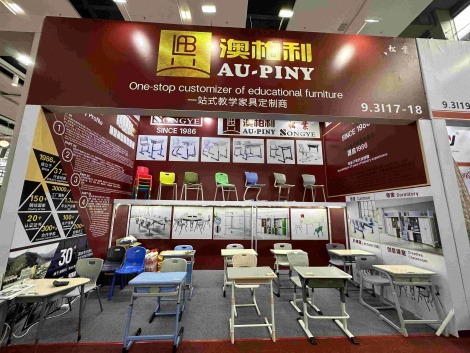

AOYASI FURNITURE CO., LTD, previously well-known as SONGYE OFFICE FURNITURE CO., LIMITED and AU-PINY FUNIRTURE Co., LTD, originated in 1986. Specializing in manufacturing and exporting school and office furniture. We are now experiencing an annual turnover exceeding USD 10 Million. Our factory covers an area of over 30,000(㎡), currently having more than 150 employees and over 100 advanced production facilities. We have separate workshops such as cutting, stamping, welding, polishing, metal surface treatment, electrostatic powder coating, woodworking, plastic working, general assembly , final packaging.

We always strictly implement ISO9001:2000 (Quality Management System), ISO14001:2004 (Environmental Management System) and OHSAS18001 (Occupational Health and Safety Management System). We have also successfully passed certification of CHINA ENVIRONMENTAL LABELLING and CQC CHINA ECOLABELLING. Our products include student desks and chairs, conference hall seating, library bookshelves, periodical shelves, book cabinets, document cabinets, office tables, bunk beds, combination bunk beds and so on. They are available in various designs and models. Our monthly production capacity is 200,000 sets of desk and chair.

Marketed under our patented brand "SONGYE" and “LAB”, our products are exported widely to overseas. 80% of our total yearly output are manufactured for exports to the Africa, Middle East, South East Asia, Oceania and other continents. The remainder of our production go to the domestic schools and retailers.